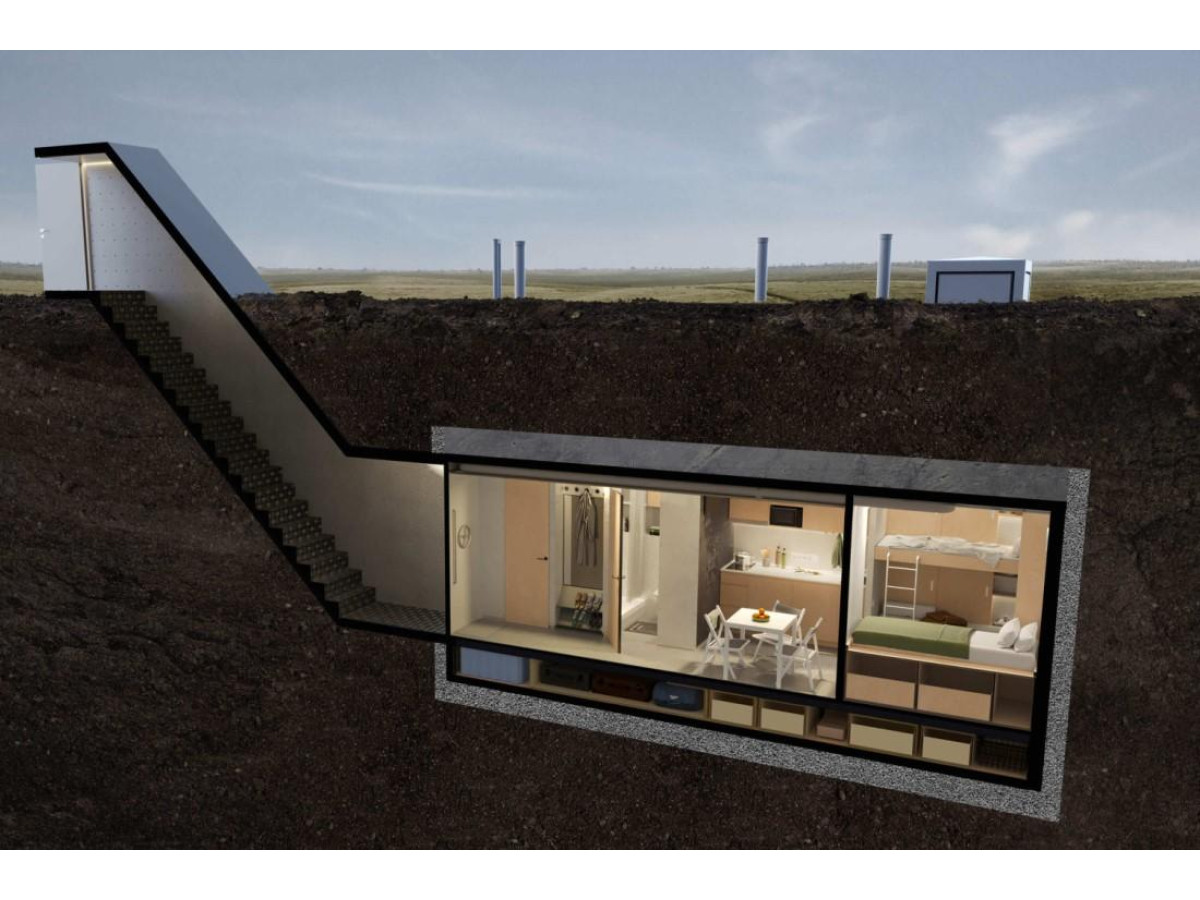

In our present, when the threat of terrorist acts and military conflicts is increasing, security becomes a priority task for our country. An important aspect of security is the arrangement of bomb shelters, which should protect people from the danger of explosions. Since all bomb shelters are located underground, it is necessary to immediately solve the issue of waterproofing and water drainage. This is the key, because it is impossible to imagine a comfortable stay in a room that is constantly damp, cold and damp, regardless of how reliable and strong it is.

To ensure the drainage of water from the underground structure, it is necessary to install a drainage layer. Lack of proper drainage can cause negative consequences such as flooding, freezing and swelling of the structure, as well as mold growth and early damage to the building. A spike-shaped membrane is considered a reliable and effective material for this.

What is a spiked membrane and what are its advantages?

The spiky membrane is a special material that has a relief surface with protrusions or spikes. This design provides improved strength, stability and drainage properties. Spiked membranes are usually made of polymeric materials such as polyethylene or polypropylene.

In the arrangement of bomb shelters, a spike-shaped membrane is necessary for several reasons:

Protection against leakage: bomb shelters are usually located underground, where the groundwater level may be elevated. The spike-shaped membrane serves as a waterproof barrier that prevents moisture from entering the room and protects it from flooding during floods or rains.

Improved strength and stability: in case of possible impacts of military operations or natural disasters, the spiked membrane provides additional protection against damage and destruction of the bomb shelter walls and ceiling.

Drainage: The relief structure of the membrane promotes efficient water drainage, which helps to prevent the formation of puddles and accumulations of water inside the bomb shelter, which, in turn, helps to maintain dryness and comfortable conditions for people.

Installation of a spiky membrane

The installation for the arrangement of bomb shelters includes several important stages that help ensure reliable protection of the bomb shelter from leakage and maintaining a favorable environment for staying in it for a long time.

Surface preparation. Before laying the membrane, it is necessary to carefully prepare the surface of the walls and ceiling of the bomb shelter. This includes cleaning from dust, dirt and other contamination, as well as leveling out irregularities and eliminating damage.

After preparing the site, the membrane is unfolded to the required size, taking into account the dimensions and shape of the walls and ceiling of the bomb shelter. It is important to take into account the supply of material for overlapping joints and areas of joints.

The membrane is attached to the prepared surface of the walls and ceiling with the help of a pressure bar or dowel-umbrellas, which ensure its reliable fixation and prevent it from shifting. It should fit tightly to the surface, without the formation of folds or folds.

To ensure additional strength and tightness of the membrane, it is important to properly strengthen the seams. K-2 butyl rubber tape is often used at the membrane joints, which provides a reliable and waterproof connection.

After completing the installation, it is necessary to inspect the installed membrane for defects or malfunctions. Make sure that the connections are tight and there are no gaps between the membrane sheets.

Next, finishing works or installation of additional layers of protective coating for the arrangement of bomb shelters are carried out.

To improve the drainage properties, as well as to prevent the accumulation of moisture in the ground, it is recommended to use a spike-shaped membrane in combination with a geotextile.

To purchase a spiky membrane or get additional advice, you just need to fill out an application on our website or contact our specialists at the number indicated below. In our warehouse, there is a profiled membrane of various densities, in rolls with a width of 2 meters, as well as all the necessary components for its installation.

.svg)

Write a comment